How a 1968 Well Became Wireline Training Grounds

How a Texas farmer built a wireline training company from a forgotten well, bringing people from all over the world to learn the art of oil and gas wireline.

This interview will leave you refreshed.

I spoke with Russell about two years ago when I was exploring ways to learn about the oil and gas industry. He directed me to his podcast, and I've been a subscriber ever since.

I bought a piece of land and it accidentally had a well on it. So I was getting clear and brush and here's this pipe sticking out of the ground and thinking it's sealed... There's no way a person could drill a well and do a school and be profitable, because the money to do that will cost so much. It was drilled in 1968, and that's when I was born.

— Russell Smith

Russell's path to the energy sector wasn't typical.

"Somebody always said the best employees in wireline are ex-rangers, farmers, and military," Smith explains. "So I kind of fit the bill." After earning an agronomy degree from Texas A&M, he joined Halliburton in 2008 at age 38, entering during the height of the shale boom.

Links

- Watch the inteview and subscribe on YouTube

- Read the Interview below (or copy/paste into your preferred AI tool)

- Visit Top Gun Oilfield Training Center

- Subscribe to All Shots Fired with Russell Smith on YouTube

- On Faith: Learn the Bible in 24 Hours with Dr. Chuck Missler

Internet Things

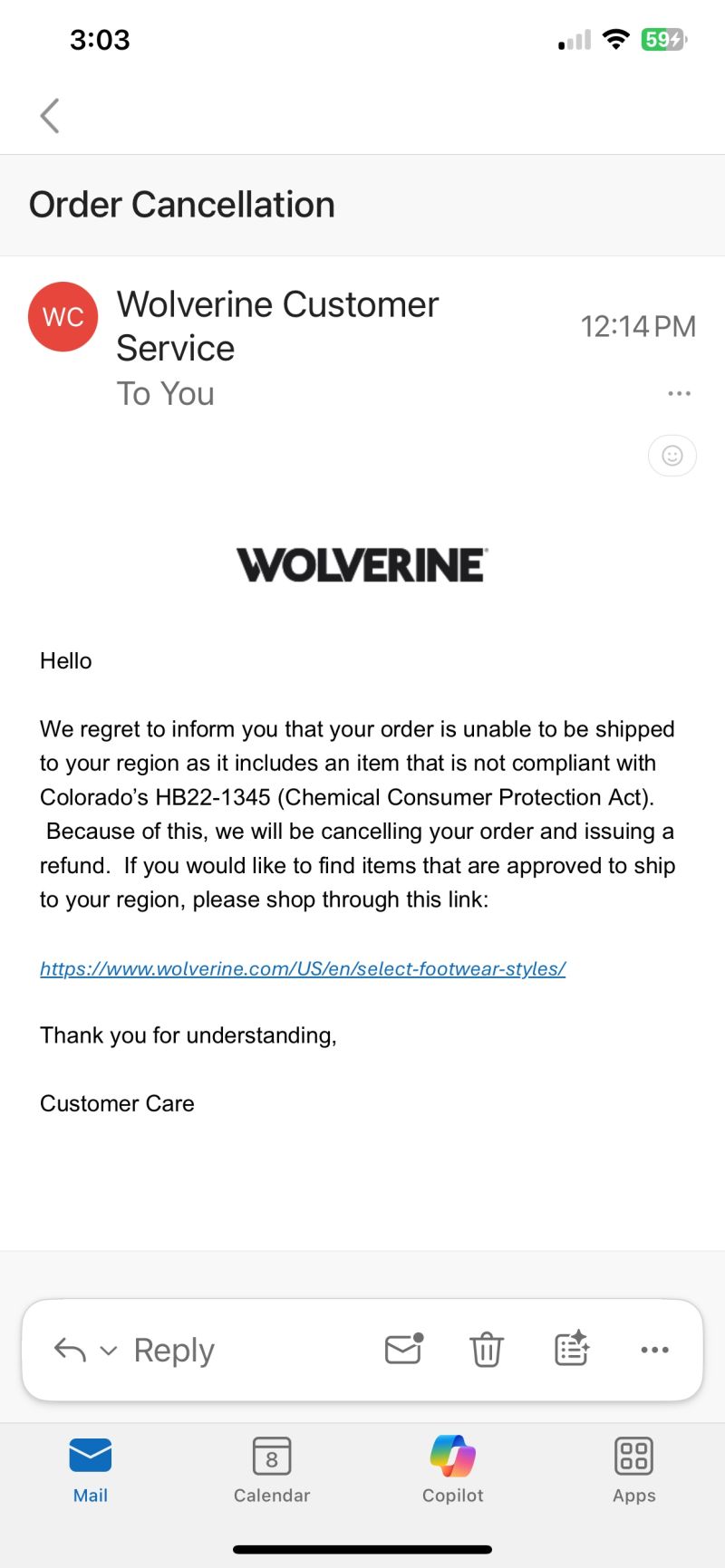

Literal Bootlegging 🙄

Colorado blocking work boots because of PFAS

Windfarm Waste

Schnorr Signature Aggregation

Good morning! Grab a cup of coffee, and lock in for a bitcoin tech thread 🧵.

— Rob Hamilton (@Rob1Ham) August 31, 2025

Today I'll do a light rambling on Schnorr Signature aggregation and current use cases, as well as some shoutouts to some of the companies pioneering the use of this in production.

Lets Begin 👇

Interview

Russell Smith turned an accidental discovery on his property into Top Gun Oil Field Training, addressing critical skills gaps in the energy industry

Russell Smith never intended to revolutionize wireline training in the oil and gas industry. The former farmer-turned-Halliburton engineer was simply clearing brush on land he'd purchased when he stumbled upon something unexpected: a pipe sticking out of the ground.

That discovery would eventually become the foundation of Top Gun Oil Field Training, now attracting students from as far away as Australia and Argentina to learn specialized wireline techniques on a working well from 1968.

From Agriculture to Oil Fields

Smith's path to the energy sector wasn't typical. "Somebody always said the best employees in wireline are ex-rangers, farmers, and military," Smith explains. "So I kind of fit the bill." After earning an agronomy degree from Texas A&M, he joined Halliburton in 2008 at age 38, entering during the height of the shale boom.

The timing proved fortuitous. "It was such a wild time," Smith recalls of the Eagle Ford explosion in South Texas. "We had no place to stay. We were driving to San Antonio to stay at the River Walk Hotel because that's where we could find a place." The demand was so intense that companies like ConocoPhillips offered job bonuses for flawless operations, sometimes adding $7,000 to monthly paychecks.

But the rapid expansion came with challenges. Smith and his colleagues were learning on the job with inadequate equipment. "We were using 7/32nd line – this little bitty wire," he says. "It was a process, but technology has changed significantly since then."

The Accidental Discovery

After growing tired of the monotonous pump-down work, Smith transitioned to a technical manager role with JW Wireline (later acquired by FTSI) and purchased rural property. While clearing brush, he discovered what appeared to be an abandoned wellhead.

"I stuck about 60 feet of joining PVC and never got to the bottom," Smith remembers. "I was like, 'Man, I don't know how deep this goes.'" A waterline truck crew reached 1,200 feet before hitting equipment limits. Eventually, with help from Jay Debra's equipment, they discovered the well extended to 4,600 feet.

The revelation sparked an idea. "I got to thinking, 'Man, I've got a hole to do this and make actual training for it,'" Smith says. After running a cement bond log and seeing the results, he realized the potential. "There's no way a person could drill a well and do a school and be profitable because the cost would be so much. For something that was given to me, drilled in 1968 – the same year I was born – it was a blessing."

Filling a Critical Gap

Smith identified a significant market opportunity. While major service companies like Halliburton, Schlumberger, and Baker Hughes provided internal training, no independent third-party training existed for wireline operations. "Anybody can come," Smith explains of his approach. "You don't have to have a big service job with Halliburton or somebody."

The need became apparent during the skills transition from vertical to horizontal drilling. "When we started pump-down work, we didn't know how to figure a rehead on a horizontal well that's 18,000 feet," Smith admits. "We could figure gravity on the vertical, but friction played such a valuable role in horizontal wells."

Industry professionals confirm this gap. Many experienced operators report encountering situations where decade-long veterans lack fundamental troubleshooting skills, such as finding shorts on wireline trucks or properly interpreting cement bond logs.

Hands-On Learning Philosophy

Top Gun's methodology emphasizes practical experience over theoretical knowledge. "We can lecture all day long, but until they actually turn the tool on and set the gates up and start seeing the winch running, then it clicks," Smith explains.

The facility includes a unique half-mile surface flow loop that allows students to experience equipment failures safely. "I can get them stuck since I'm on surface," Smith says. "I can put stops in and make them experience really bad situations. They'll pull out a rope socket, and I'm like, 'You just cost a lot of money.'"

This approach addresses a critical industry challenge: transferring decades of field experience to younger workers. "Experience teaches you everything," Smith emphasizes. "Until someone experiences problems, do they really grasp what's going on?"

Global Reach from Rural Texas

Despite operating from a small facility in rural Texas, Top Gun attracts international students. Smith runs both supervisor classes (10-day comprehensive training) and specialized cement bond logging courses (2-3 days), typically hosting one session monthly or accommodating custom requests.

The training covers both technical skills and client relations. "Company men are alphas," Smith notes, teaching students strategic communication approaches. "Get them to talk about themselves, ask them questions, and they'll think you're the best person in the world."

Technology and Interpretation

Smith emphasizes the importance of proper log interpretation, particularly the Variable Density Log (VDL). "I teach guys mostly how to read the VDL because I can't manipulate it, I can't change it, and it'll tell you if you've got cement or not," he explains. This focus on data integrity addresses industry concerns about subjective interpretation affecting operational decisions.

The shift from printed logs to PDF delivery and remote operations monitoring represents significant technological advancement. Some companies now monitor multiple wireline operations simultaneously from Houston offices, with single operators overseeing five trucks remotely.

Industry Evolution and Future Challenges

Smith entered the industry during an unprecedented boom period when "they were hiring anybody with a pulse." The current environment presents different challenges, with higher stakes and less tolerance for learning curves. "Half the mistakes we made wouldn't be acceptable now because there's not enough activity," he observes.

The skills transfer challenge remains acute as the industry ages. Smith's solution involves comprehensive scenario-based training that compresses years of potential field experience into intensive weeks. "A guy told me I probably taught him 10 years worth of experience in a week by teaching him all the bad stuff that can go wrong," Smith reports.

Beyond Technical Training

Smith integrates broader life philosophy into his technical instruction, drawing from his Methodist upbringing and engineering mindset. He credits a company man's recommendation of Chuck Missler's "Learn the Bible in 24 Hours" series for providing analytical frameworks that enhanced his teaching approach.

"The more you study it, the more you go, 'How can I not believe this?'" Smith reflects, applying similar logical analysis to both spiritual and technical subjects. This comprehensive worldview influences his teaching methodology, emphasizing practical wisdom alongside technical competence.

The Bottom Line

Top Gun Oil Field Training represents successful entrepreneurship born from industry necessity and accidental opportunity. By combining practical experience with systematic instruction, Smith has created a unique educational resource addressing critical skills gaps in wireline operations.

As the energy industry continues evolving with remote operations and advanced technology, the fundamental need for hands-on training and experienced judgment remains constant. Smith's approach of learning from controlled failures in a safe environment offers a model for technical education across industrial sectors.

The story also illustrates how individual initiative can address market gaps that larger corporations overlook, creating value for both service providers and operators while advancing industry-wide competence standards.

Top Gun Oil Field Training offers monthly courses at topgunoilfield.com, along with online RP67 explosive training certification and educational content through their "All Shots Fired" podcast series.